How to weigh a train? Understand now

Just like any other item that is used for transportation, such as trucks, for example, trains also need to be weighed to ensure that there is no excess load. Weighing a train ensures that the maximum and minimum parameters allowed are being followed, preventing any structural damage to the railway asset itself and the railway network as a whole.

In addition, accurately weighing certifies for all parties, the selling and purchasing company, that the correct amount of cargo is being transported. Thus, as you may be imagining and occurs in several areas, there are different technologies that can be used to measure the weight of a train.

So, do you want to know the main existing ways of weighing a train? Too easy. See this article until the end and find out the ways in the market to calculate the weight of a train and also the main models of railway scales that are available in the market.

Content Index

Scale types for weighing a train

What equipment is normally used to weigh? If you imagined a scale right away, know that it is right. This is the most common equipment when weighing is required, and it would be no different when it comes to trains. In this way, know now the 4 main types of railway scales that exist:

Static Scale

A first model of an existing railway scale used to weigh a train is the so-called static scale. This equipment requires that the train be stopped on the weighing tracks, which can directly affect the speed of flow of a production, consequently resulting in higher expenses for the company.

Static weighing takes time and resources due to the need to maneuver wagons for individual weighing at the terminal. It is usually used for loading or unloading wagons with a low daily flow, or even in terminals with little space. The static scale consists of three main modules, a rigid platform that can be built of metal or concrete, which must be the size of the wagon to be weighed, a load cell sensor set and a weight indicator set. Weighing occurs wagon by wagon in a static way, the wagon being weighed disengaged from the composition, which is time consuming but on the other hand results in a very accurate weighing.

Dynamic Scale

A second model of railway scale widely used for its ability to optimize the weighing process is called dynamics. Through this scale, it is no longer necessary for the railway asset to be stopped to calculate its weight, it is enough that it passes over the weighing rails at a predetermined speed for the measurement to take place.

Thus, unlike the static model, this scale version, for example, promotes less energy expenditure, since it is no longer necessary to make the movement with the “walk and stop” train. Models with Accuracy Class of 1.0, 0.5 or 0.2 can be found on the market, for example.

Flow Scale

In comparison with the other two models presented so far, the flow scale has a different way of acting. In this case, instead of weighing the load already placed on the wagons, either static or dynamically, there is a direct calculation of the weight of the product that will be or was transported.

This is possible through a continuous flow of cargo that passes through the scale, where it generates a final weight, without the direct need to weigh trucks and wagons. During its operation, this equipment is attached to the granary or port hopper, depending on the location being weighed.

Batch Scale

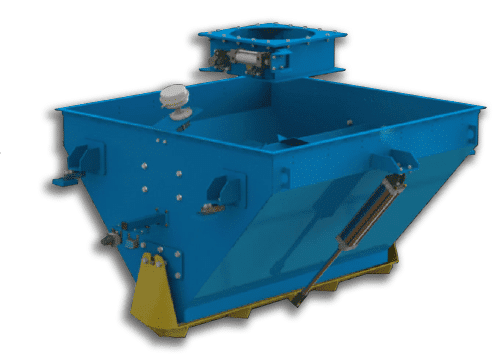

A fourth model of existing railway scale is the batch scale, which succinctly uses a cyclical process and weighs samples with equal sizes and with a pre-determined frequency to define the weight of the load. In other words, the batch process can be defined as the one in which the material transfer or material processing functions are cyclical with repeatable results.

As in the case of the flow scale, this equipment must also be coupled to the granary or port hopper for it to work. If there is no correct installation, it is possible that an error occurred in the verification of the weights.

How to weigh a train?

After the presentation of the main models of railway scales that exist, it is clear that through dynamic and static scales there is greater precision when weighing a train. Thus, to even help to understand how these models can actually weigh a train, see below:

Weigh a train for a In motion rail scale

As mentioned earlier, a in motion rail scale works from a system that allows the train to pass over the weighing tracks installed in the railway network at a certain speed and to be weighed. This weight measurement has an advanced system that is automatically connected with an operation center, where all information is directed.

In this way, with the analysis of an operator specialized in the system, the weight on the axles of the wagons or entire wagons is verified, being also possible to determine the total gross and net value transported.

For this purpose, during an unloading process, for example, the In motion rail scale can be placed before the hopper or in adjacent lines. Meanwhile, in the loading process, it is best to have it, afterwards or on adjacent lines of the wagons. For terminals with a large flow of wagons, the most common installation is that of two In motion rail scales, one before the process (loading or unloading), weighing the tare of the wagons or the gross, depending on the operation, and one after the process, also for gross or tare weighing depending on the process.

Anyway, dynamism and speed during weighing is the main mark of this type of scale, which guarantees the control of a very precious asset in the industrial environment, time. Thus, to get an idea, depending on the model chosen, weighing up to 100 wagons can be carried out in 10 minutes.

Weighing using a Static Scale

Requiring the train to be completely stopped for weighing to be carried out, the static scale has the same basic positions as in motion rail scale. However, unlike this other model, the static balance is outdated within the current industrial scenario, as it requires a greater expenditure of time and money, being indicated only in specific operations.

Even so, in the case of a small demand for daily wagons, this can be an adopted model, since it can also offer with certain precision the load that exists in each wagon.

Conclusion

In short, weighing a train can be a complicated process if techniques and the right scale for demand are not used. However, weighing a train is essential to ensure that the entire railway structure remains intact and there is no need for maintenance or adjustments, leading to an even greater expense.

Did you like our content? So follow us on Instagram we let you know when we have new articles.