Metrology and quality: important variables in the production of railroad scales

In all areas of life in capitalist society, metrology and quality are a pair that must always be present in companies. For a business to evolve and achieve more results, it is necessary to combine the two. In the matter of railroad scales, MASSA works as much as possible combining metrology and quality.

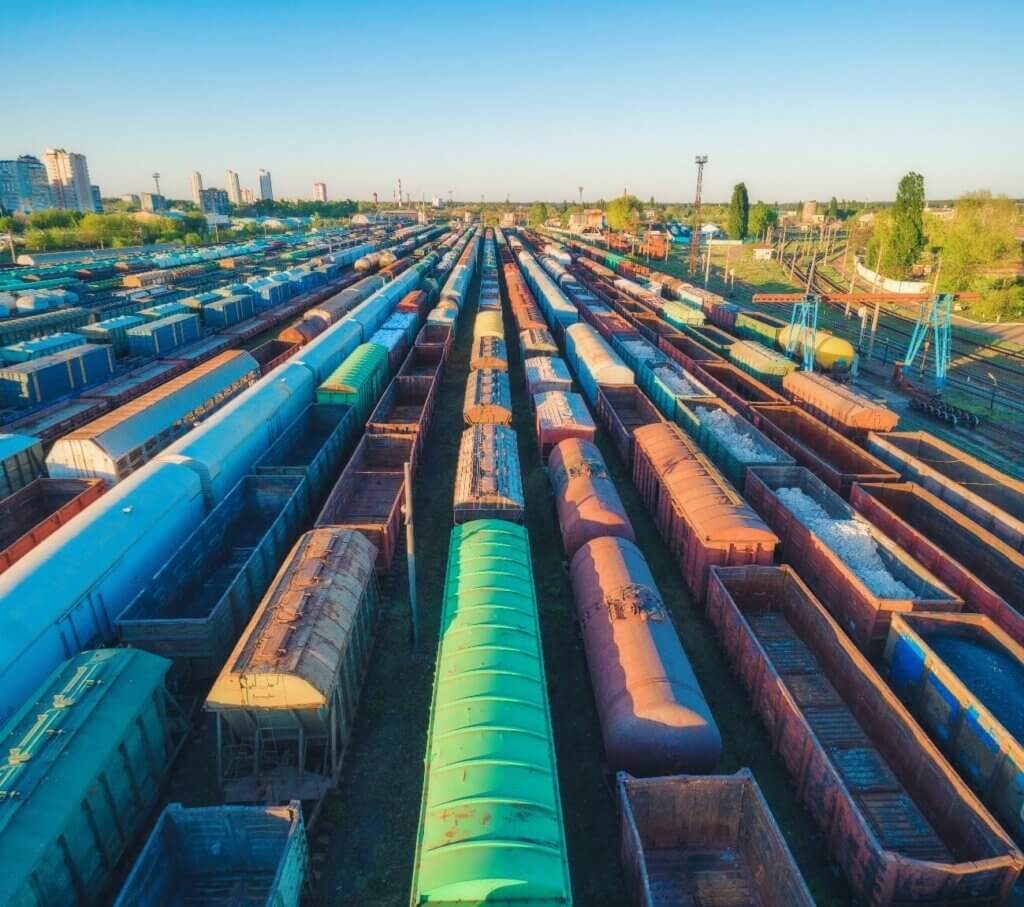

As we know, rail transport is the most recommended for large-scale displacement. This means that, both in financial and logistical terms, the quality of rail transport is usually the best when compared to other modes. Even for this reason, the railroad networks need to rely on the famous railroad scales.

As Brazil does not have the rail network as the main means of transporting cargo, and unfortunately in many railroads old scales are still used, which ends up taking away the precision of the final product, in the sense of not guaranteeing the customer the 100% correct result . Therein lies the problem of not working with metrology and quality.

Content Index

What is metrology?

Scrutinizing the term metrology a little more, we can say that the basic concept of the term is the science of measurement. That is, the science that studies all theoretical and practical aspects related to measurement. In simpler words, it is what gives you guarantees regarding the production process, whether in the industrial, scientific or legal scope.

First, we need to understand a little more about the terms involved within the concept, such as magnitude and measurement. The measurement, in this case, would be the set of analyzes that define the value of a quantity. The latter, on the other hand, would be something that can be qualitatively distinguished and quantitatively determined.

For example, when we take this to the industrial environment, there are several habits that can be considered measurements. This means that, within the production process, measurement would be the most common activity, since there is a huge range of things that can be measured. To combine metrology and quality, then, it is necessary to compare one quantity with another, in order to always seek the best results.

In fact, this is one of the great advantages of companies that have products with tested and validated metrics. In the case of Massa's railroad scales, there is the use of the concept of equipment calibration, which would be nothing more than the comparison between measuring instruments, measuring the results and analyzing each of the uncertainties. In this way, what is presented to the customer is metrologically proven.

How does metrology affect the quality of a railroad scale?

Diving once and for all in the subject of railroad scales, well-defined metrological processes are extremely fundamental in production and use. As we said above, perhaps the main objective is to avoid errors, different values between the amount of the product paid and received, failures and in some cases accidents.

In addition, perhaps the greatest beneficiary is not the customer, but the owner of the company. After all, buying and selling with a guarantee of the amount received and paid (using metrology and quality) only increases the customer's trustworthiness with the company. Even for this reason, MASSA values this aspect a lot.

How does the MASS calibration system work?

When it comes to balance calibration, MASSA does not miss any detail, always concerned with meeting the customer's schedule and improving the weighing process as much as possible. The company used the technology and nowadays it is possible to calibrate the scales via smartphone. Leaving even the practical, fast and efficient calibration.

In general, the calibration system is completely standardized. That is, as in more normal and usual scales in our day-to-day, the calibration of scales is done through load cells installed in railroad structures. In this way, it is only necessary to carry out the technical assistance of the scales that the weight of your merchandise will be guaranteeing. By the way, at MASSA you have support and an extended warranty!

Metrology and quality: Why is the MASSA railroad scale the best?

Specialist when it comes to railroad scales, MASSA offers three types of scales to its customers {1% (SIMM S-10), 0.5% (SIMM S-05) and 0.2% (SIMM S-02)} . That is, depending on the process that the customer has and the product that will be weighed, a specific scale will be indicated. It is also worth mentioning that, in addition to presenting the individual weight of the wagon and the train, the MASSA scales also provide the weight per axle, bogie and load distribution by quadrants.

All these factors contribute to greater control, allowing alignment between metrology and quality. After all, the measurement of each part of the train allows the railroad operator to identify any problem, keeping the balance always with the maintenance up to date..

In addition to being efficient and accurate, MASSA's railroad scales guarantee you support, extended warranty, installation and project that varies from customer to customer. It is also worth remembering that they have a capacity to weigh 160 tons.

That said, we can say that MASSA invests in metrology and quality not only to ensure accuracy, but for the satisfaction of delivering the greatest possible accuracy to its customers.

Conclusion

Therefore, if you are in need of a railroad scale and you didn't know which company combined metrology and quality, now you know that MASSA is the right place for weighing.

In addition, as the country is gradually expanding its rail network, MASSA is aware of the importance of using maximum technology on the scales to keep up with this evolution. In other words, selling low-level products does not match the company's history.

And it is still a company that is always developing more and more technology in its scales. It currently serves the largest companies in the rail sector in Brazil and some international companies!

If you are interested in knowing more details, visit the website website and read more about our dynamic railroad scales!!