What is Industrial Automation?

It is not new that human beings try to facilitate their daily tasks with the help of equipment that mechanize certain functions. Practical examples of this issue are the wheel, windmills, water wheels, among other objects. From this scenario, the understanding of what industrial automation is about becomes more palpable.

When taking this concept to a scope of large-scale production, it becomes totally unthinkable that the human being performs all the necessary functions, being necessary to count on the help of devices that automate tasks. Based on this model of thought, around the second half of the 18th century, in England, everything begins to change in industries arriving today with the processes we know.

So, do you want to know a little more about these changes and how industrial automation is the weapon that any successful company needs to use? It's very simple. Read on and learn more about this concept, and also learn about the idea of industry 4.0

Content Index

What is industrial automation?

Based on the idea of enhancing and facilitating tasks, as mentioned earlier, industrial automation is nothing more than the optimization of industrial techniques used to produce a product through the use of different hardware and software technologies. However, this process cannot and should not be understood as the permanent substitution of people's work for that of machines.

The industrial sector has evolved and, consequently, its professionals and professions would also go through this process. As a result, while functions are finished without logic within this new dynamic, others appear according to the new needs, requiring direct human participation.

Therefore, the primary function of automation within the industry is to create greater self-sufficiency for equipment and machinery, reducing the need for human beings to perform specific functions within the production chain. When thinking about working with heavy machinery, this reduces the chances of an accident and also, in a way, generates greater uniqueness to the product.

In order to be able to carry out this process, it is necessary to integrate at least three different areas: electronics, mechanics and information technology (IT). Without there being, in fact, an integration between these units, automation can be more harmful than beneficial for the company.

Given this scenario, automation has become almost a mandatory activity for corporations that wish to stand out and remain competitive in the market. Without it, productivity and profitability rates tend to fall, creating problems for the business cash flow.

The difference between industrial automation and mechanization

As already mentioned, one thing that should be made very clear when dealing with automation, regardless of where it occurs, is that this change does not imply the total removal of people from the production process. In this way, this is the basic difference between an automation and mechanization process.

Although at first, they seem to have similar meanings, they represent almost opposite actions. While automation goes to the processes we have already mentioned, industrial mechanization simply calls for the use of machines to carry out the functions, without any physical effort.

Benefits of Industrial Automation

Because it is a practice that seeks to optimize processes within an industry, industrial automation has several advantages for companies. Below, we list, we list some of these benefits, check out:

Production Line Efficiency

Perhaps the first advantage noticed with the adoption of processes that automate the industry is the fact that the production line starts to act more quickly. Since machines can work 24 hours a day without rest and are less prone to failure, the volume of goods produced becomes greater.

In addition to this aspect, there is also a possibility of greater flexibility in the production line. This is because it is faster and also easily programmed, it is totally possible to perform the so-called just-in-time production, which means manufacturing only what correspond to the demands.

Security for employees

Adopting automated systems in your company also contributes to the safety of the entire work environment. As all human beings are subject to errors, there is always a risk that, accidentally, an operator fails in an activity and this creates a serious problem for his/her health as a consequence.

Therefore, when doing business automation, the company is obliged to follow strict regulatory standards, which, among other things, requires the adoption of specific safety practices for the operation of each machinery. In addition, a computer-operated system is not at risk of making these mistakes.

Quality of products

In addition to being more efficient in the production steps, automated systems also have testing and verification steps that can be programmed to ensure product quality. Thus, the industry can have a greater guarantee that the final product will present the desired characteristics and that please the consumer.

Analysis and Control

The process of improving the activities carried out also benefits from automation. This is because automated systems generate a high volume of data that can be measured. With that, it is possible to have greater certainty when making any decision to improve the business.

Industry 4.0

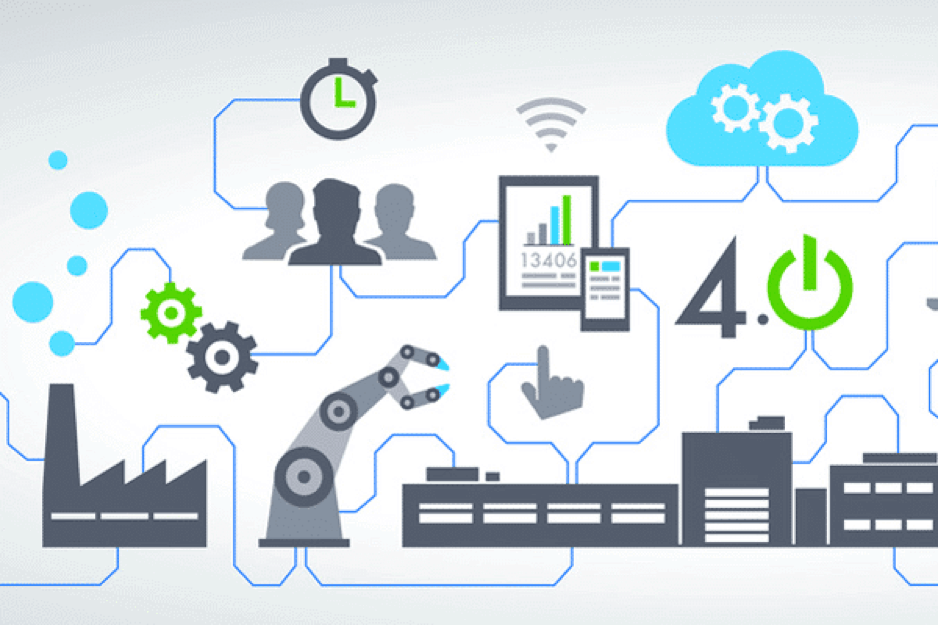

Together with automation, the idea of industry 4.0 can also emerge. This concept, which emerged in 2011, seeks to encourage the decentralization of control over production processes, always through the use of technology and automation to make the connection between processes and factory environments.

Thus, a factor that marks the presence of industry 4.0 in a corporation is the fact that there is an interconnectivity of the entire operation. This industrial management model also seeks to reduce costs and increase the load of goods produced.

Conclusion

In short, automated systems are able to raise a factory to a level of competitiveness within the much larger market, managing to offer an product of extreme quality and that is ready in a short time. Mass Weighing and Industrial can help you with this. Click here and know more.